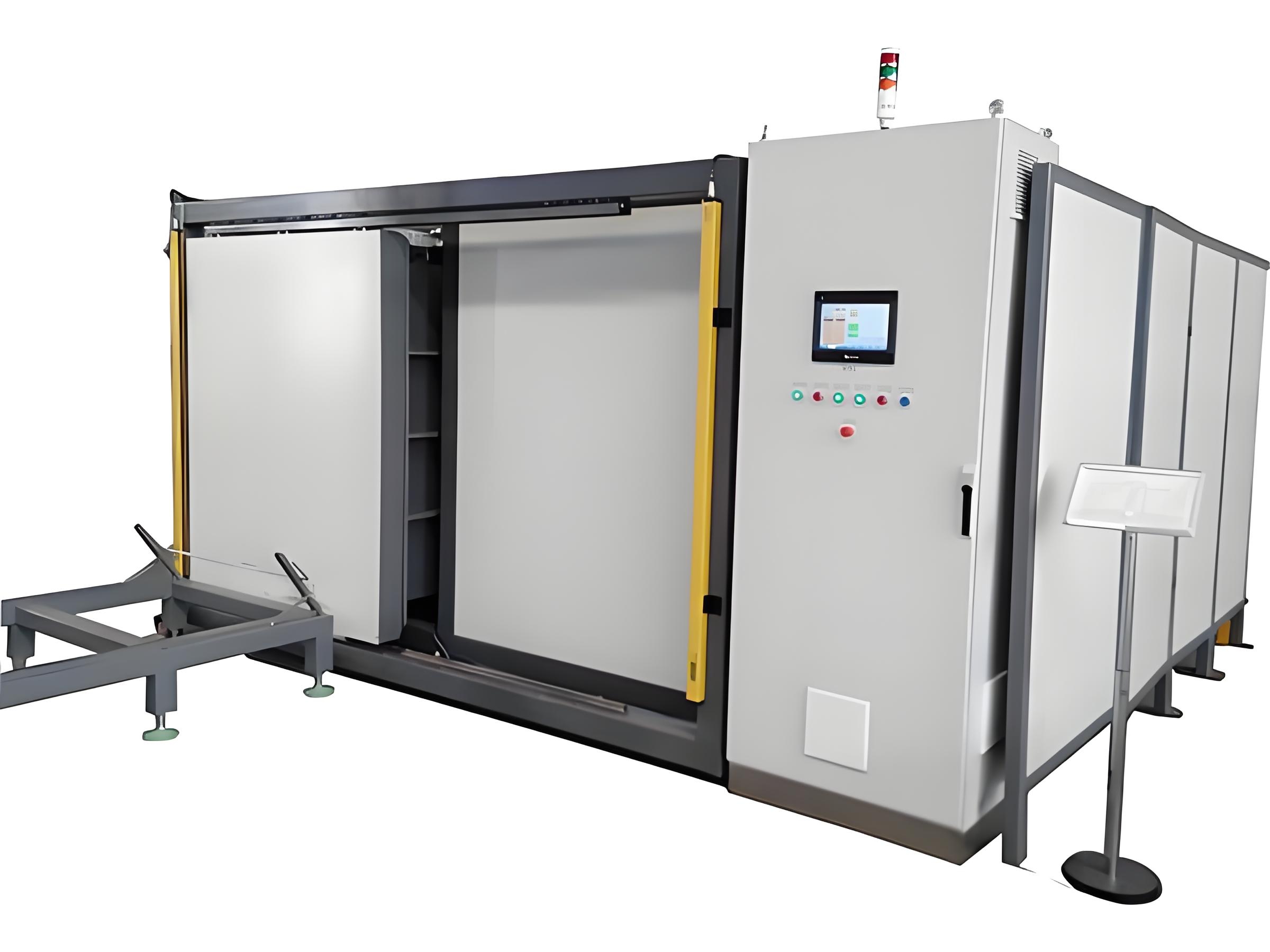

Vacuum box helium leak detection system - Power Industry

It is mainly applied to products such as switch cabinets, gas-insulated switchgear, ring main units, and power castings in the power industry. The inspected products have large external dimensions and large internal volumes. Due to the very thin wall thickness of most cabinets, the pressure difference between the inside and outside cannot exceed 0.05Mpa. Therefore a vacuum box and the workpiece need to be used for synchronous vacuum detection.

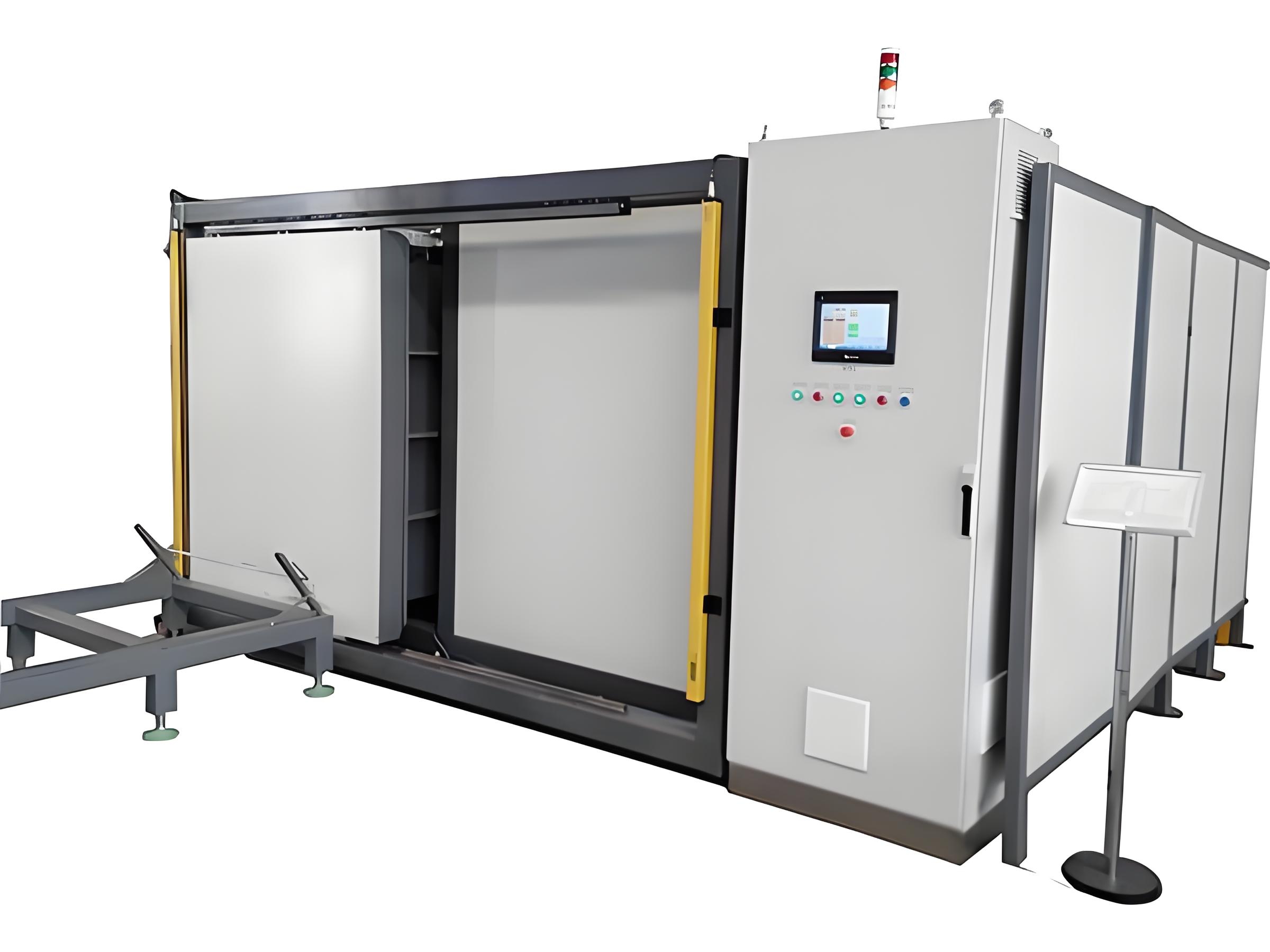

Vacuum box helium leak detection system - Power Industry

It is mainly applied to products such as switch cabinets, gas-insulated switchgear, ring main units, and power castings in the power industry. The inspected products have large external dimensions and large internal volumes. Due to the very thin wall thickness of most cabinets, the pressure difference between the inside and outside cannot exceed 0.05Mpa. Therefore a vacuum box and the workpiece need to be used for synchronous vacuum detection.

▲ Detection accuracy :SF6 annual leakage rate 0.1%-0.5%;

▲ Detection cycle time :30 minutes -60 minutes per box;

▲ The inner cavity size of the vacuum chamber: Customized according to the shape and size of the inspected workpiece;

▲ Vacuuming method: The vacuum box and the workpiece are vacuumed simultaneously.

▲ Door opening methods: left and right sliding doors, box-moving type;

▲ Nitrogen recovery rate :98%;

▲ Control mode :PLC control, touch screen operation;

▲ Degree of automation: After manual connection of the workpiece, the door is closed, vacuum is simultaneously evacuated, helium is filled, detection is carried out, recovery is completed, and SF filling is fully automated.

▲ Safety protection: Grating protection, built-in safety switch, electrical interlock, hierarchical password control, sound and light alarm;

▲ Configuration: The system adopts high-end configuration to ensure reliable and stable performance